SCHOOL PROJECTS

Designing a Makerspace for Santa Fe Indian School

WPI Interactive Qualifying Project (IQP)

Project Description: WPI requires all majors to complete an IQP while providing the opportunity to travel and work on a community based project. Preparation to travel to Santa Fe, New Mexico began in A-Term (End of August) and the team of interdisciplinary majors arrived in New Mexico end of October. The team had the opportunity to work with the Santa Fe Indian School and conduct social science research by interviewing teachers and local makerspace employees from Santa Fe and Albuquerque. Because the team was only working on the project for a total of 15 weeks and only in Santa Fe for 7, we weren't able to see the actual makerspace be made. Our project goal was to design a makerspace that would unify individual efforts by Santa Fe Indian School staff to increase accessibility to hands-on STEAM education. And by generating four objectives we were able to give Santa Fe Indian School a comprehensive Guide with recommendations for how they can build and implement this makerspace and STEAM program.

Process Improvement for Tech Pizza

A Local Worcester, MA Restaurant

Project Description: For my BUS3020 class (Achieving Effective Business Operations) I worked with a team of students to analyze a local business close to campus. After talking with the the family owned business Tech Pizza we were able to work on the project by following the seven step improvement process by conducting time studies and analyzing how the business operates on a daily basis. After watching how the business operated the team was able to create journey maps, process maps, and value stream maps. After conducting time studies, the team was also able to calculate takt time and standard work for different processes. By the end of the 7 week project, our team offered the business owner a potential method to reduce the cost of running the business. Because he doesn't have the infrastructure to record what people purchased there was know way for him to forecast purchases, only buy things when he got low or anticipated needing them. The team provided him with a physical tracking sheet where he can record what people purchased and an excel sheet so he can see the history easier. By tracking what was purchased he can start to see weekly and monthly trends and better adapt his business towards what sells.

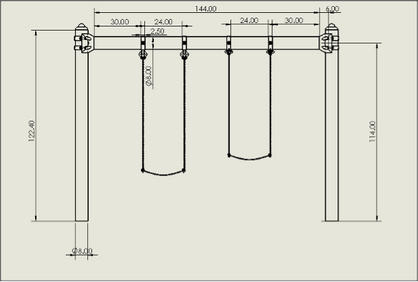

Stress Analysis Project - WPI

Project Description: For my ES2502 (Stress Analysis) I worked with a team of interdisciplinary students to make a CAD model of a playground structure and conduct load tests in ANSYS software with various forces. One force being an extreme case likely never to occur, and the other a normal case one. Using ANSYS the team recorded the total deformation, equivilant elstic strain, normal elastic strain, shear elastic strain, equivilent stress, normal stress, and shear stress. In addition to having ANSYS calculate forces, stresses, strains, the team was tasked with manually calculating the normal case stress, strain, and deflection. The team also calculated Shear and Bending Diagrams for the normal case.

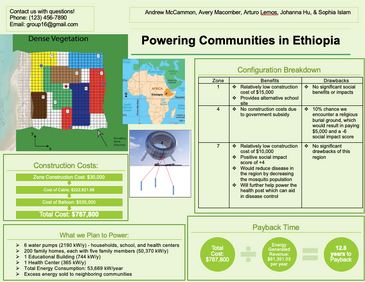

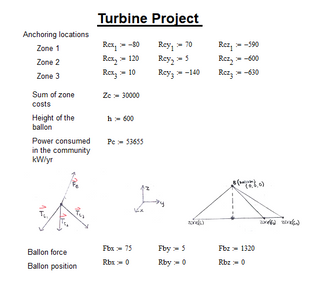

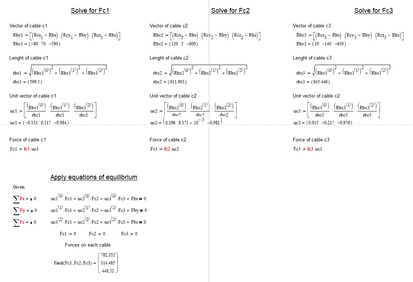

Statics Turbine Project - WPI

Project Description: I worked with a team of interdisciplinary students to determine where to anchor a floating wind turbine. The team had to consider social implications, cost analysis, and physical considerations to make sure the turbine could withstand different wind forces. Using MathCad the team developed a program to easily repeat calculations when we changed anchor locations.

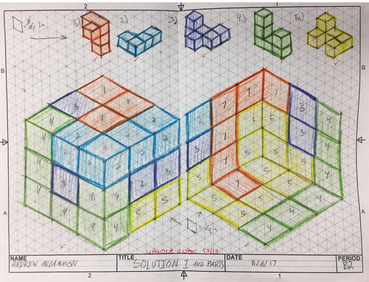

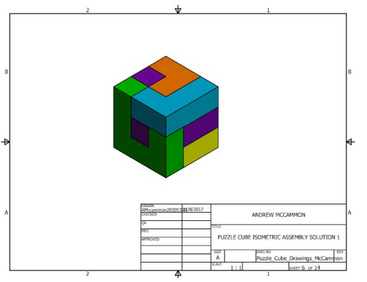

Puzzle Cube Challenge - DHS

Project Description: In my high school pre-engineering class every student was tasked with designing two puzzle cubes each with different solutions, and each with 6 different interlocking pieces. The goal was to help an imaginary furniture company use leftover scrap wood reduce production costs and waste. The project started with each piece being sketched and then built in autodesk inventor. After each piece was designed, assemblies were made in inventor as well. Once design the CAD models were complete, the physical puzzle cubes were made in addition to packaging so the product could be "sold."